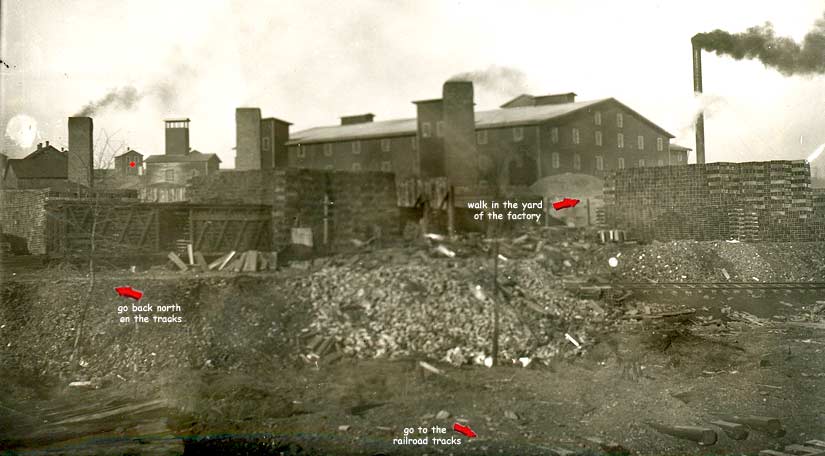

A very prominent feature of the village

of Clermont for about 60 years was a manufacturing activity known as the

Tile Plant. This was a large factory located in the very heart of the village,

and it provided a livelihood for about 100 families for most of its lifetime.

This activity consisted essentially of four major parts: first, the

mine which supplied the raw product which was fire clay; next, the

manufacturing plant which formed the ceramic tile; then, the kiln complex

which fired the tile; and finally the storage yard where the finished

product was stored pending sale and shipment.

This facility existed from 1904 until 1961. It operated from 1904 until

about 1930 with infrequent and brief interruptions for maintenance. About

1930 the worldwide depression caught up with the business and this, coupled

with the fact that the telephone lines in the large eastern cities had

all been pretty much rerouted underground, ended the need for the product

being manufactured. So the operation was shut down in 1930 or 31. For the

next 15 years it was idle most of the time, but every now and then there

was enough demand for the product so the plant could be operated

for a month or two.

Attorney John G Whitmore of Ridgway was instrumental in the formation of

the Clermont Sewer Pipe Company in the village. This company was chartered

by the State Department of the Commonwealth of Pennsylvania in February

1904 with a capital stock of $150,000 fully Paid. The new company's

officers were President, M. F. Quinn, Straights, Pa; V.P. CF Barclay, Sinnemahoning,

Pa; Secretary and Treasurer, WE Ringrose, Binghamton, NY. The principal

stockholders were Quinn and Sherman, Straights, Pa; Attorney John Whitmore,

Ridgway, Pa and Barclay Brothers, Sinnemahoning, Pa.

In April 1904 ground was broken for the new plant. On the first of March

1905 the sewer pipe factory was turning out goods, and expected to operate

at full capacity that Spring. WE Ringrose was plant superintendent, and

he lived with his wife Clara in the superintendent's house on the south

side of the street from the plant office. This house is now occupied by

the Johnson family.

Ringrose continued as superintendent until November 1920 when the

Clermont Sewer Pipe Company was sold to a New York firm, and the name was

changed to the International Clay Products Company. Ringrose then retired,

and Jack Allison, who had been shop foreman, was slated to follow Ringrose.

Instead, he was offered and accepted the post of McKean County detective,

and moved

to Smethport.

At this point Hohn A Clay became superintendent. He had held the same

position at the Sergeant Glass Company at Sergeant until he came to Clermont.

He had a bad fall at the plant in Clermont in early 1925 and resigned.

He died at 55 on May 17, 1925 in Port Allegany.

The post of plant superintendent was taken over by H. K. Leighow. He was a

native of Kentucky and had operated similar plants there. He continued

until operations ceased in the early 1930�s. In 1948 it was taken over by

the Kaul Clay Company of Toronto, Ohio and operated for 12 years. In November

1961 it was totally destroyed by fire.

This enterprise was a dominant feature in the community for very nearly

60 years. It was initially located in Clermont because of the deposit of

suitable clay some 60 to 80 feet below the surface in most places. This

was a dense burning plastic fire clay with a vitrification range around

1800 to 2300 degrees Fahrenheit. The fired product ranged from a faint

red to various shades of brown from light tan to dark brown.

The plant was originally built to manufacture salt-glazed, vitrified

sewer pipe, and this was the product, in various sizes and shapes, until

just after World War One. In this time period telephone and telegraph wires

in the nation's large cities were all on poles, and the proliferation

of communication lines suspended from poles was becoming a real problem.

The alternative was to put the lines underground. Some sore of conduit

was necessary; it had to be practically indestructible and completely non

reactive. Fired clay pipe was the ideal answer, and sewer pipe manufacturing

was easily adapted to the manufacture of tile conduit. It was in fact a

simpler process as there were no complicated fittings, elbows, reducers,

collars, wyes, etc.

About 1919 the plant switched to this product. Western Electric Company,

the manufacturing subsidiary of AT&T became the primary customer. Conduit

in various sizes from singles through 9-hole were manufactured until the

plant ceased operation in 1929

When Kaul Clay took over in 1948 it required some rather extensive repair

and overhaul after which the manufacture of �hot-tops was started.

These were essentially steel crucibles, i.e., a container for molten steel,

which when it was cooled, became an ingot. This was a one use item; when

the ingot was cool enough to be self standing the hot-top was simply broken

up and discarded.

In 1948 when this refurbished plant started to manufacture hot-tops,

the railroads into Clermont had since been abandoned and the tracks taken

up. So transport of the product to various steel mills in Buffalo, NY;

Sparrows Point, Md; and others, was by highway trucking. The raw

material consisted of a bed of clay from 5 to 7 feet thick, essentially

horizontal, 60 to 70 feet below ground. A thin seam of coal also occurred

with the clay (every 7th car from the Big Soldier's Mine carried coal),

and was mined to augment the import of coal for the plant boilers. Before

1948 the coal was mined by underground room and pillar mining, but Kaul

Clay initiated strip mining in the surrounding area. Some of the

miners (about a dozen at a time worked 7 to 4) included Aaron Miller,

Fred Hagman, Dick Johnson, Fred Henry, Joe and Dominic Cecchi, Fred Rice,

Fred Murray, Willard Rounsville, Art and Curt Marshall and Bill Henry.

(On Saturday, March 31 1923 Willard Rounsville lost part of his arm when

a blasting cap detonated). Harry Flickinger was the mine superintendent.