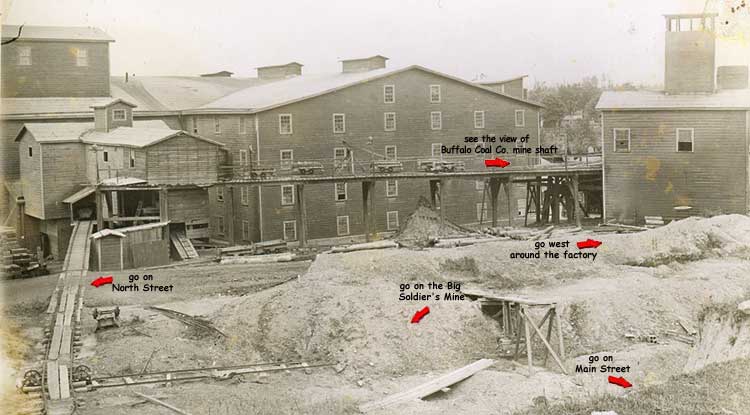

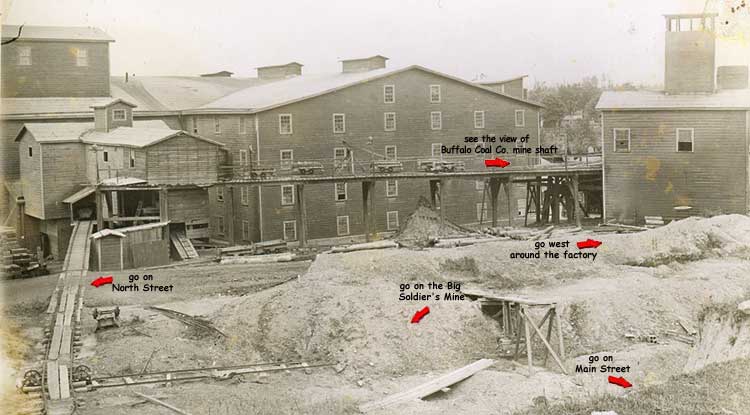

later called Kaul Clay Factory

The view looking south west

photo credit: Clermont Reunion 2000

Clermont Tile Company (built 1901) production:Small clay chunks, obtained from the adjacent underground Big Soldier's Mine, were brought into the plant on trams (in the above photo a tramway is visible along the side of the plant), transferred by elevator to the top floor, and ground to dust. Water was mixed with the dust to make a firm slurry which was placed in a steam operated press containing a set of dies for the desires tile size. Pressing produced a wet tile form that was stored on the plant floor for several days of air drying (steam heated pipe ran throughout the entire building) before being fired in kilns.

Kilns are domed structures with fireboxes on the outside. Several kilns were placed around one chimney or stack. Hot air circulated from the firebox, through the tile, out the bottom of the kiln and up through the stack. When tile needed a special glazed finish, salt was shoveled on the firebox coals. The plant had many kilns and stacks.

Clermont Tile initially made building tile for walls, foundations, and flues. As other materials replaced these products, it changed to drainage tiles four to 36 inches in diameter plus hot tops, a large square shape used for casting ingots in the steel industry. Production of the smaller size tiles was about a 1,000 per hour.

The four story wooden building held two large tile presses with remainding space used to store thousands of wet tiles. Everything was destroyed in a huge fire on November 21, 1961. As Kaul Clay had another tile making plant in Ohio, no consideration was given to rubuilding. Competing plastic pipe had also began to erode the clay tile market.

text credit: James Herzog