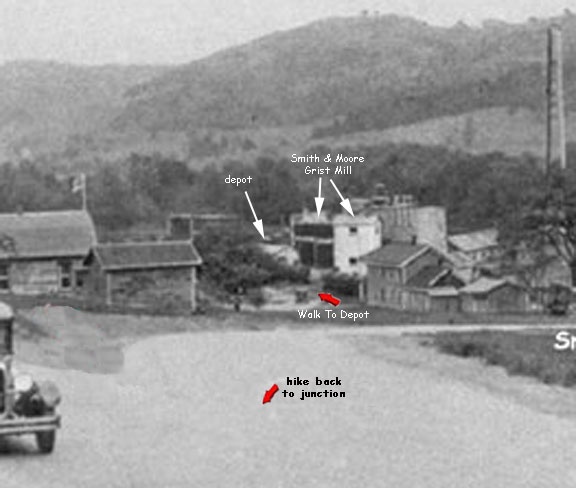

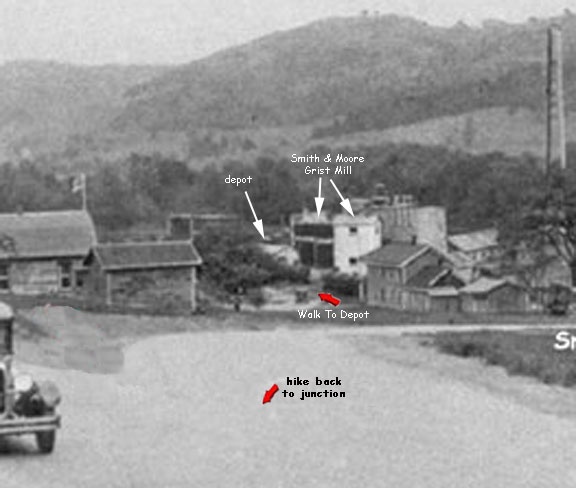

1874: Smith & Moore Grain Mill

Read an article about the Smith & Moore Grain Mill.

|

A representative of the Miner visited the new and finely constructed grist mill of Smith & Moore, at Farmer’s Valley, on Monday and tells what he saw as follows. The mill is a three story frame building 36x50 situated near the depot, easily accessible from the highway and railroad, having every facility for loading and unloading grain either for shipment or to be carted away. Piloted by Mr. Casper Smith and his millwright, Mr. Wm. C. Ackley, we first visited the engine room, here we found a beautiful horse power engine which cost $1,000 manufactured by the celebrated firm of McEwen Brothers of Wellsville, NY. The engine is a gem of its kind, working quietly and steadily and requiring but little fuel to run it in comparison to the amount of work required of it. One of the first, noticeable features in the mill is the total absence of mill banding, it being so arranged that even on the ground floor the shaft runs underneath the flooring, thus not only enabling the proprietors to utilize every inch of space but preventing the many accidents so common in mills and factories where the rooms are intersected with mill banding. Stepping from the engine room to the grinding room, on the ground floor,, which contains three of the finest quality of stones, two 86 inch and one 30 inch costing $800 each, near by we noticed a curious little machine which on inspection we found to be a corn sheller manufactured by Sellew & Popple of Dunkirk, NY. This machine, although costing but about $75, is capable of shelling more than 30 bushels of corn an hour. The arrangement of the elevators are worthy of comment, one in particular on this floor especially adapted for custom work, and so partitioned of that every customer can see at a glance just how much flour etc., he is getting. On the second floor is the machine for which this mill is justly celebrated. It is called a Middlings Puritier, manufactured by Huntley, Holcomb & Heine, value of $300. The grain after being ground is brought up by elevators to the third floor, passes through the “bolt” into another elevator, then into the “bran duster” from thence into the “separator,” which separates the bran from the middlings, and then into the “purifier”. It is impossible to speak too highly of this machine. By the courtesy of Mr. Bartholomew, the miller, we were permitted to examine a portion of the middlings just taken from the “purifier” under a powerful microscope, each particle of wheat showing itself perfectly pure and white without a single speck of bran or dust. The machine itself blows the dust into another room and the grain passes down into the stone again to be re-grounded, thus making a quality of flour of a purity impossible to be manufactured on the old time principle. The Enreka Smutter, Bran Duster and Separator, manufactured by Hown Babcock & Co., of Silver Creeek, valued at $300 and $175 respectively are machines lately invented and, it is needless to add, do their work effectively and well. The dust from the Smutter is blown from the third floor, thus leaving no dust in the mill. All machinery on the second floor is propelled by friction from a shaft running through the ground floor, so that no belting is required. There are three granaries on this floor each capable off storing 400 bushels. On the third floor is an “ExcelsorBran Duster.” The latest improvement in this machine is what is called a “Jar” to prevent the machine from clogging up. None of the machines in the mill have been out of order yet. A useful little arrangement on the ground floor, a Patent Sleeve Sprout, will be thankfully remembered by farmers who are accustomed to having their sacks torn in filling. This simple contrivance entirely prevents that, being movable and easily adjusted. The “bolts” are worthy of notice being each supplied with nine slides by which the flour can be transferred by any of the elevators back to the stones to be made into either first, second, or third quality. The bolt gearing was all gotten up by the McEwen Brothers, of the latest and most improved methods, and the fixtures and arrangements throughout are, without exception, as complete as any mill in Pennsylvania. The mill commenced to run early last fall and we are glad to say business has been steadily improving since. During the last two months more than a car load of grain per week has been ground. At a cost of at least $10,000 Messrs, Smith and Moore have built this mill and put it in its present admirable shape for business. No pains(?) or money has been spared to make it the best of its class, and equip it with every improvement in the way of machinery that will guarantee the best kind of work. Not only the proprietors, but every client has good reason to be proud of it as a home institution worthy of praise and patronage. |