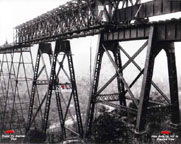

photo credit: John Marconi Collection

Chanute awarded the bid to The Phoenix Bridge Works Company. General Kane met with Anthony Bonzano of the Clark Reeves Division of the Phoenixville Bridge Works Company of Phoenixville, Pennsylvania, in early 1882. Mr. Bonzano told General Kane, "We'll build you a bridge a thousand feet high if you'll provide the money." Anthony Bonzano along with Oliver W. Barnes, who was the chief engineer for Kane's railroad, joined up and planned the first Kinzua Viaduct. Work on the stone piers began in 1881 and took six months to complete. The massive sandstone blocks used to make the stone piers that support the extremely high iron columns were quarried from the nearby hills. They are in great supply and of an excellent quality. There were 7,600 cubic yards of hard sandstone used in the stone work of the viaduct. The stone piers were embedded as far as thirty-five feet below the ground and as high as sixteen feet above the ground. John C. Noaks was in charge of the stone work for the first viaduct. There were bolts that measured six to ten feet long and one and a half inches in diameter embedded in the 110 stone piers for the attachment of the vast amount of iron work. On September 8, 1881, the cornerstone of the Kinzua Viaduct was placed on the south abutment, where it remains today.

Erection of the ironwork began on April 10, 1882. There was a temporary

railroad track laid into the valley to assist the workers on the bridge in the

distribution of the large amount of iron work. The Kinzua Viaduct was

constructed of stone and iron completely with the only wood being the railroad

ties and railings. There were twenty lower spans of thirty-eight and one

half feet, and twenty-one intermediate spans that measured sixty-one feet.

The tubular wrought iron columns, which measured nine and three quarters of

an inch in diameter, resembled logs and led to the mistaken belief that the

bridge was constructed of wood. Tie rods were used to aid in the stability

of the bridge. There was no scaffolding used in the construction of the

bridge. All that was used was a rig called a gin pole to build the first

tower and after that a wooden crane was built at the top of the first tower

and the second tower was built using the crane. This process was repeated

to construct the rest of the towers. There was also two steam hoists

used to aid in the construction of the viaduct. Amazingly there was thirty

miles of manilla rope needed for the tackle and block used. In 94 working

days the 40 man crew had completed the highest and longest railroad bridge ever

built. It was 301.5 feet high and 2,053 feet long with the tallest tower

having a spread of 103 feet. The thirty-six workers were paid two to three

dollars a day and the four foremen made five to six dollars a day. The

total cost of the original structure was $167,000 and contained 3,105,000 pounds

of Iron.

1883

Kinzua Bridge 1883

Kinzua Bridge |

1900's

Kinzua Reconstruction 1900's

Kinzua Reconstruction |

2000

Kinzua Bridge 2000

Kinzua Bridge |

2003

Kinzua Bridge Collapse 2003

Kinzua Bridge Collapse |