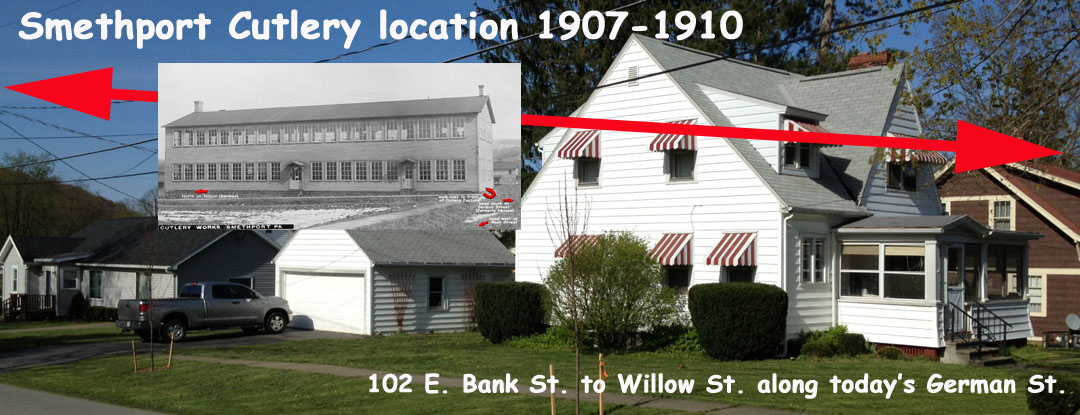

1907-1910: Smethport Cutlery Origin & History

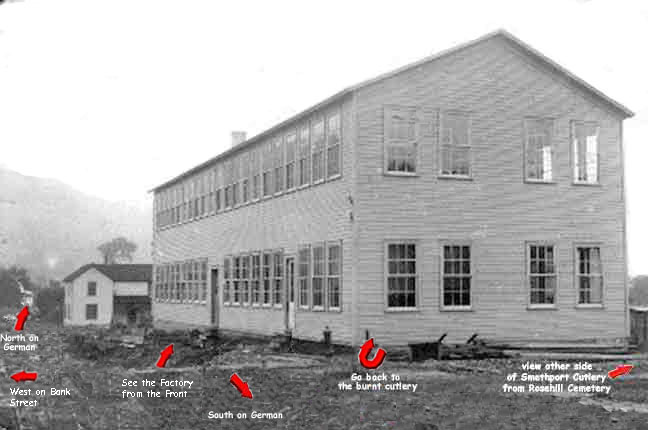

102 Bank Street

photo credit: McKean County Historical

Society Collection

see knife factory location today!

What I like to refer to as the westward migration of vintage cutlery manufacturing continues to be of great interest to me. The voyage of these killed craftsman and keen businessmen entrenched in the development and distribution of knives and related items, reveals much about the American industrial revolution and entrepreneurial spirit of those early cutlery pioneers. Some of these manufacturers were in business for multiple decades, while others succumb to hard times rather quickly, albeit fostered by poor management, natural disaster, or just plain bad luck. Near the turn of the 21st century, many of the little known manufacturers throughout the Northeast produced high quality products, but their inability to market them for whatever reason made it nearly impossible to continue the business successfully and compete against the larger concerns. One such company was the short-lived Smethport Cutlery Company of Smethport, Pennsylvania. Smethport is only about 17 miles from the famous cutlery town of Bradford, Pennsylvania, and just about 50 miles from Little Valley, New York, another vintage cutlery-manufacturing stronghold during the same frame. We know for a fact that trained cutlers regularly switch employers in hopes of better wages and other bonuses used as enticements for changing their loyalty. Many times, they took techniques and designs along with them. Remember that in 1903, C. Platts’ & Sons Cutlery of nearby Eldred, closed down and was immediately replaced by the Eldred Cutlery Company, using many of the former employees. Some waited until 1905 and moved on to Bradford when the newly formed W.R. Case and Sons Cutlery Company that bought out the Platts’ Company and took on Harvey N. Platts as secretary/superintendent of the factory. It is no surprise that others sensed the lucrative business of cutlery manufacturing and thought it may be an opportunity to add another industry in their town too. The area had abundant cutlers and if a good source of power could be harnessed, all that was needed was the support of community and/or its leaders, along with finances to get the business off the ground and running. The following article printed in the McKean County Miner on January 24, 1907, certainly seems to illustrate that process. An enthusiastic meeting of stockholders of the proposed new cutlery plant was held at the hose house Thursday evening and at this time the following board of directors was elected: Charles McKean, H. H. Redfield, T. H. Pancoast, S. L. Fry, O. J. Hamlin and Wm. Monheimer. Owing to the absence of some of the newly elected directors, the election of officers and other important business was deferred until the next meeting, which will be held within a few days. At this time a president, secretary, treasurer and other necessary officers will be chosen, application will be made to the governor for a charter for the new company and other matters attended to. A site has not as yet been selected, but the proposition together with the style of building will be left with the directors who will decide these things within a very short time. These gentlemen have a very desirable location. At Monday evening’s meeting a name for the new company was decided upon which is “Crescent Cutlery Company,” It was also agreed upon that the first payment of 10% on the subscribed stock shall be made February 1st and after that equal installments of 20% on the first of each month. This plan should meet the approval of the stockholders. In conversation with one of the directors last night a MINER representative was informed that the cutlery plant for Smethport was a sure thing and that the plant would be in operation by the early spring. He also stated that unless weather became more favorable operations on the building would not begin until the first of March. The prospects for the new concern are bright and no doubt, it will become a leading factor in the business life of Smethport. Every citizen of this borough should be interested in this concern. Not all could invest money in it, but now that it is certain that the cutlery factory is a “sure go,” every man woman and child can invest interest and show their appreciation for what has been accomplished for the town. The men at the head of the Crescent Cutlery Company are honest reliable, bustling businessmen who have labored untiringly forward the landing of this manufacturing plant an they can be depended upon to successfully conduct the business in the future. And last but not the least a boom to Smethport and the Crescent Cutlery Company. Certainly, it appears on the surface that the group and the town were welcoming the business with open arms and wallets. Mr. McKean was a wealthy lumber and oilman with connections in the community as were many of the board of directors. One might conclude that it was hailed as a economic savior for the little town of Smethport. No different from today’s business atmosphere, many factors play into the eventual success or failure of any start up. Smethport actually provided a site for the factory free of charge on the south side of town at the corner of Bank and Nelson Streets. Unlike many other similar cutlery startups, it appears that none of the founders came from a strong cutlery management background. Typically, these businesses had at least one or more experienced members to help avoid the known pitfalls of this type of industry. In March of 1907, the same newspaper provided this progress report on the fledgling company. You will notice that the name has changed from Crescent Cutlery to Smethport Cutlery. This may be due to the existence of a Crescent Cutlery associated with the Northfield Knife Company in Connecticut. The site was decided upon a few days ago by Charles McKean, S. L. Fry, representatives of the Cutlery Company and a committee from the Smethport Land & Improvements Co. There had been two sties for consideration, one from the Shawmut Railroad Company and another from the Land & Improvement Co., but as the latter were willing to give a clear title to the land that site was selected. The Shawmut people would only give a site consideration that the cutlery company guaranteed them a certain amount of freight per annum and this the latter did not wish to do. The Smethport Land & Improvement Co. will give the Smethport Cutlery Company a deed to the property as soon as operations begin in the plant. To this company the people of this borough need to extend a vote of thanks for it is a generous net on their part, especially when it is taken into consideration the amount of land that is given and desirability of it for building purposes. The dimensions of the land are 198 X 103 feet, or the size of three regulation borough lots. It is a most desirable location as the land is high and dry and will be well protected in case of fire as there are two hydrants in the immediate neighborhood, one at the corner of Bank and Nelson Streets and the other at the corner of Willow and Nelson Streets, or one block away. As to the nature and plans of the building, we are unable to state with the exception that the factory will be a two-story frame structure: about 100 X 40 feet in size. A representative of the company informed us yesterday that in a few days a charter will be granted then preparations will begin toward the erection of the building and this work will be pushed to completion wish as much haste as possible. Mr. Eckert, the superintendent, will arrive within a few days and then the necessary machinery will be ordered so as to have it here by the time the building is finished. To some persons it may seem as if this is not a desirable location for the factory because of it being a considerable distance from railroad facilities, and to counter this we learn that a through investigation in Bradford, Eldred and other towns having cutlery plants revealed that they are not built in close proximity to the railroads. After the materials and machinery have arrived, there is not much use for the railroads because most of the product is shipped by express. Another very good reason for building on the south side is to give the property owners of that locality a chance. For they have paid taxes to help other sections of the borough and the result has been that the other sections have greatly increased in value while that locality has not increased with rapidity of the others. With the establishing of the cutlery plant in that neighborhood, it will tend to place a higher valuation on property. There is still stock in the plant which can be obtained by any persons so desiring of Charles McKean, president of the company, who will be pleased to give any information that is desired. It appears that not everyone was pleased with the new company’s choice of location, but the newspaper certainly was defensive of the venture. One of the reasons for its positive spin on the new company was that this newspaper was a stockholder in the business. Advertisements for Smethport Cutlery products tell us that production was limited to pocketknives only. This would have allowed for a smaller labor force and wouldn’t have required employees skilled in multiple cutlery applications, such as shears or straight razors. The Daly & Garlick Hardware Company of Smethport advertised quite proudly that a line of pocketknives manufactured by Smethport Cutlery Co. had been added to their huge knife inventory. We do know that straight razors were made in Smethport by the Backus Company, but it was not a part of the Smethport Cutlery operation as current research has shown. Backus was well known for the manufacturing of a unique security item that deterred the theft of your hat by locking it up while visiting a public establishment. If you had the opportunity to read the article entitled ‘Raising Kane’ in the May 2012 issue of Knife World Magazine, you will recall that the Case Bros were going through some dramatic changes with their knife production at about the same time. On October 28, 1907, the Titusville Herald reported that a proposed ‘sure thing’ with John D. Case ended up being a bust. J.D.C. insisted upon complete financial control of a new plant to be located in nearby Warren, Pennsylvania, but the shareholders would have no part of it. The Case Bros were on the hunt for a new location to expand their businesses. Unfortunately, we know that the Smethport company was short-lived for reasons we can only speculate on at this time. Perhaps the location wasn’t as good as they thought, management lost interest, materials too expensive or maybe labor problems or a combination of many factors, but all we know for sure is that it didn’t operate for very long and lasted only a year or so. In May of 1909, Case Bros decided to purchase the Smethport Company for $85,000. The offer supposedly was a very good price and presented in such a manner as to specifically entice the Case family into purchasing it. The local newspaper printed the following on May 11, 1911. If the plant is sold it will be operated here for a long term of years as price is practically agreed upon if all stockholders will consent to sell. It looks now as though the Smethport cutlery factory, which has been idle for a long time, may be sold in a few days to thoroughly practical men in this business and if this deal is consummated this plant will be started in operation in a short time with a large force of men with good prospects of its running full time for a long term of years. For the past three months Horace H. Redfield has been corresponding with these parties relative to the sale of the this plant and matters have progressed so far that these prospective buyers are expected here in a few days to look over the plant and it its proves satisfactory after inspection as deal will be closed at once. The committee that was given power to dispose of this plant, of which Mr. Redfield is a member, has offered it at a very reasonable figure and we feel certain that the prospective buyers will realize that they have a good thing and take advantage of it without delay. On the other hand it will be a good thing for the stockholders if the plant is sold at the proposed price, because there is a mortgage against it that will be foreclosed in a short time unless something is done with the plant so that the holders of this mortgage can get their interest: and if the plant was sold at forced sale to satisfy this mortgage the chances are that it would not bring enough to pay the claim, let alone allow stockholders anything. Of course if this deal goes through the stockholders will be losers on the original investment, but as half a loaf is better than none, we as one of the stockholders thin it is the best thing to do. The newspaper’s influence worked and the Case Brothers made the purchase. In April of 1910, it was reported that: “Since the Cases took hold of the Smethport Cutlery works, a few months ago, there has been something going at that plant every minute and from present appearances there is going to be more doing under the capable management of these practical cutlery men. At present, we understand there are about 25 hands employed at this plant and this number, as we understand it will be constantly added to as conditions warrant. It is further understood that Messer. Case will soon begin the erection of an addition to their large and well equipped plant in this borough which will give them additional facilities for carrying on their extensive business. As this is one of the best of the Company’s string of cutlery works, it is safe to say that before the season is far advanced the Smethport cutlery plant will be one of the busiest industries in town. The DEMOCRAT was informed this week that already ten families will in the near future move to Smethport on the account of starting of this important industry, and more are sure to follow as hands are added to the work force at this plant. Altogether the outlook at the cutlery works are most propitious for a busy season, all of which will be good news to every citizen who has the best interest of Smethport at heart. It also reported “Several hands have been engaged since Monday of last week assembling the unfinished stock on hand at the cutlery plant. This rather slow work as the Smethport Cutlery Co.’s inscription must be ground off all the knife blades and that of the CASE BROS. substituted. Another reason knives stamped Smethport Cutlery are so difficult to locate. All was going well for the salvaged cutlery company and it looked as though Case Bros was going to succeed with this new addition to their growing dynasty. Fate had different plans though as the June 16, 1910 issue of the McKean Democrat stated. The Smethport cutlery plant was entirely destroyed by fire Friday evening. Shortly after eight o’clock last Friday evening fire was discovered on the first floor in the North end of the extensive cutlery works on the corner of Banks and Nelson Streets in this borough. When the alarm was given the fire had gained great headway, and the flames were seen issuing from the building by those who happened to be in position to get a view of the plants. The Hose Company promptly responded to the alarm, but some little time was lost before the fire was located. The firemen had a long run, and when the did get on the ground, and made connections to nearby hydrants, it was soon discovered that they could not get sufficient water to be of any assistance in checking the fierce blaze that had by that time enveloped the building, and the fire had about its own way, and soon communicated to Lewis Ramer’s bar, which was located on the opposite side of the street, in which was stored several wagons, and farm machinery, and to the adjoining barn owned by John Brigsby. These buildings and contents were about a total loss, while the residences of Frank Burdick, S.J. McKendrick and George Hackett were threatened with destruction. For some reason or other the steamer had to be hauled to the fire by hand and as the machine weighs 6,000 pounds the task was not an easy one, and as a consequence the cutlery plant was doomed before the steamer was located at the Nelson Street bridge ready for business. After the streamer got to work, it did good service in checking the spread of the fire to adjacent property, but the greatest damage had been done – the total loss of the cutlery plant, one of the best of its kind in the country. This plant was erected a few years ago at a cost of $15,000 and was equipped with machinery at an additional expense of about $10,000. Up to last fall the plant was owned by Smethport parties who for a time operated it, but subsequently the works were shut down and remained idle until the Case Bros. purchased the plant a few months ago and started the works up, since which time they have been in constant operation, and between twenty and twenty-five hands were being given steady employment at the time of the fire, and the owners expected to add about twenty-five additional hands to the working force after July 1st, and it is said that the force would have been increased to seventy-five or one hundred before winter. So the loss is a serious one to Smethport as viewed from a business standpoint. The fire, which is of a mysterious origin, started in what was known as the furnace room in the North end of the building. When the night watchman, who was on duty, first made the discovery the fire had then gained great headway, and notwithstanding he made an effort to check the ravages of the flames, he soon discovered that they were beyond his control, and the alarm was sent in. The Case Brothers, besides the plant, had a stock of between three and four thousand dollars of finished work ready for shipment on hand, besides much unfinished stock. On the building and contents, they only had an insurance of $12,000. Their loss was total one. It would seem as though it was about time for a through inspection of every fire hydrant in town, and not only that but the hydrants should be inspected at frequent intervals, so as to be sure that they are in working order. It is a most inopportune time to find out that no water can be taken from a fire hydrant after a bad fire has broken out. It is quite interesting that in 1907 the newspaper touted the virtues of having fire hydrants in close proximity to the site, three years later the plant burns down and can’t be saved due to the malfunctioning of the hydrants. In today’s world, a lawsuit of epic proportions would most likely be filed and the Case Bros would have stood a very good chance of winning it giving the conditions surrounding the loss. Two weeks after the fire, it was reported that if the citizens of Smethport would raise $2,000 to assist in the purchase of the existing Cut Glass Co., the cutlery plant would be relocated there and remain in Smethport. Much of the heavy machinery was believed to be salvageable from the remains of the original structure. Supposedly, a group did raise the funds, but other concerns or opportunities envisioned by the Case Brothers derailed the relocation of the factory. This reversal of loyalty to Smethport was not well received and hard feelings over the loss of industry remained for quite some time. Less than a month later, the Case brothers were back in Warren, Pennsylvania negotiating the relocation of the factory to their town under favorable conditions. In August 18, 1910, about two months after the Smethport fire, the McKean County Miner reported rather sarcastically that: The Warren Mirror of Friday has the following to say in regards to the Case Bros Cutlery Co., whose plant in this borough was destroyed by fire some time ago, and who subsequently decided to move to Warren Pa. in spite of the fact that the Smethport Cut glass Co’s factory building on Water Street was offered to them for a very small sum and about $2,000 had been pledged by public spirited citizens of this place to keep the industry here. “It is practically assured that Warren will have another good industry”. John D. Case and Brothers whose reputation of knife manufacturers is widely known have decided to locate in Warren under the provision that they be given a site suitable for their use. They feel that the businessmen of Warren can afford to give them $1,500 and this has been agreed to providing sufficient subscriptions are received and this is beyond question. The lot selected is near the corner of Parker Street and Penn Ave and is well adapted for the purpose. It will cost $1,800 but the Case Company will pay $300 of this amount and make an agreement not to have it deeded to them in a less period than ten years. The Case company say they will start business here with a least 35 men and expect to have a hundred employed within a year. Most of the men are mechanics and will draw good wages. The proposed building will be cement and brick and two stories ground base 40 X 100 feet. It is understood that most of the machinery which passed through the fire at the local plant can be repaired practically good as new and it seems passing strange that the owners of the industry with the factory facilities available at a sacrifice figure and a neat bonus extended to them, not to speak of the fact that they at present own a fine factory site here, would go to the big and unnecessary expense of erecting a new plant and moving their outfit to Warren where much smaller inducements have been offered according to foregoing article from the Mirror. We know that the relocation never happened and some feel it was just a ploy by the Case Brothers to obtain more cash to continue the Little Valley, New York operation. Needless to say, a similar fate awaited that plant in Little Valley in 1912. This second fire devastated the Case Bros operation and it wasn’t long after that the famous TESTED XX trademark became the property of the W.R. Case & Sons in Bradford. The Smethport operation never reopened and products of this factory are of high quality and extremely hard to find. As a dedicated collector of Pennsylvania related cutlery items, this remains the only pocketknife-manufacturing town that isn’t represented in my vast collection. I can only hope that someday someone scrapes the rust off an old knife at the flea market and sees SMETHPORT on the tang, then runs home to the computer to contact me to buy it. I am waiting by the keyboard now! -David L. Anthony, Erie, Pennsylvania Knife World Magazine |

McKean County Miner THE CUTLERY FACTORY IS CINCHED FOR SMETHPORT. |